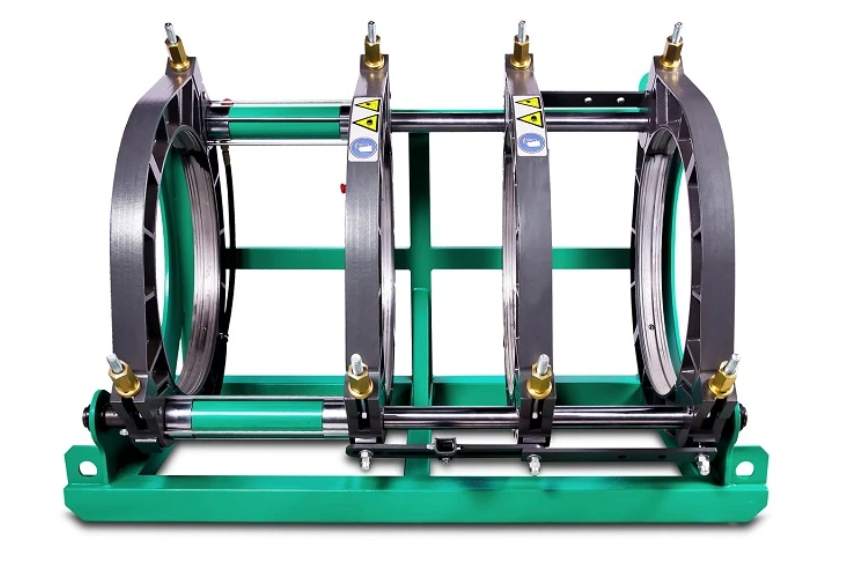

Automatic Butt Fusion Machine FHD630 CNC 315MM-630MM (12" IPS -24'' IPS)

| Categories | Automatic Butt Fusion Machines |

|---|---|

| Brand | Flossuretek |

| Model | FHD630 CNC |

| Certificate | CE, ISO9001 |

| Packing Material | Plywood Box |

| MOQ | 1set |

| Range in inch | 12 |

| FOB port | Shanghai |

| Terms of Payment | L/C, Western Union, T/T, Paypal |

Detailed Information

Hydraulic Butt Fusion Machine V630 CNC 315MM-630MM (12″ IPS -24” IPS)

The FLOSSURETEK V-CNC series automatic hydraulic butt welding machine FHD630 CNC is applied to joint PE, PP, PPR, and PVDF pipes and moulded fittings.

Selection of components with a long service life ensures a low maintenance and repair, friendly and reliable operation.

- Water Infrastructure: Ideal for joining thermoplastic pipes in water supply networks, guaranteeing secure and leak-free connections.

- Gas Distribution Systems: A reliable solution for welding pipes in gas distribution systems, ensuring the integrity of gas infrastructure.

- Industrial Pipelines: Suited for a range of industrial applications utilizing thermoplastic pipes, providing durable fusion joints.

- Mining Industry: The V355 excels in the mining sector, delivering efficient fusion welding for pipelines critical to mining operations, ensuring dependable and durable connections for water, chemicals, or other resources.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FEATURES

Basic Frame

Featured by

– Oil seal kit, origins from Germany, make sure that the pressure performance stays in a more stable way.

– 4sets quick coupling helps the operator to prepare the machine better before and after welding, and we use STUCCHI which from Italy ensures no hydraulic oil leakages when unplugging or plugin.

– Using an integral shaft (top chromate treatment) instead of the assembled shaft, ensure the chassis strength to avoid possible frame twist or deform when dragging the pipe with extreme parameters.

Heating Plate

Featured by

– We use Dupont from the USA for coating the heating plate, which is the best in the industry. It’s many stickers on an aluminum plate, more non-sticky to plastic pipes surface. The temperature deviation of different points on the heating plate is 2-3 degrees (small size machine) and 5-6 degrees (big size machine).

Trimmer

Featured by

– High-quality drill, which can do 220V, 3phase as an option.

Electrical box Assy.

Featured by

– Temperature-controlled switch when the temperature-controlled switch is off, all the aviation plugs are not live, even the power cable connected with the power source. It is quote safe to connect or disconnect the plugs before or after welding.

– Very well-connected wires and a more reasonable layout. Each wire is marked with the corresponding numbers, thus giving more convenience to do the troubleshooting when a failure happens.

Support

Featured by

– Ergonomic design

Automatic Control Box

– The CNC hydraulic control box is available for all RIYANG basic model machines, covering the size from O.D 50mm through O.D 1200mm. A fully encased control box makes the protection level up to IP 54.

– Due to the unique powertrain, it could not only create sufficient hydraulic power during the welding procedure but also makes sure precise control. And most importantly, it greatly reduces the weight of the control box. And the servo-motor applied significantly reduces the failure possibility and maintenance cost.

– All connections sockets are located at the back of the hydraulic control unit, including sockets for the trimmer tool and heating plate. No additional power distributor is needed.

– Various welding standards (DVS, ISO, WIS, etc.) could be pre-installed by different languages upon your request. All welding reports could be saved immediately to internal memory with a capacity of 2000 reports after welding accomplished, or print the report. Meanwhile, it is available for downloading through the USB interface.

– All RIYANG V-CNC series hydraulic control box is featured with PLC touch screen, extremely user-friendly RFID access technology. Troubleshooting and program upgrades are available for remote control.

– When the heating plate hooks up with the machine chassis, inserting or release the heater will be controlled remotely by a hydraulic unit, which is the same as a trimmer. These characteristics prevent the operators from being injured.