| Categories | Hydraulic Butt Fusion Machines |

|---|---|

| Brand | FLOSSURETEK |

| Model | FHD160 |

| Certificate | CE, ISO9001 |

| Packing Material | Plywood Box |

| MOQ | 1set |

| Working Range in mm | 63mm – 200mm |

| Working Range in Inch | 2″ – 6″ IPS |

| Working Pressure Range | 0 – 80Bar |

| HDPE Welding Standard Applied | ISO21307, DVS2207/1, ASTM F2620 etc. |

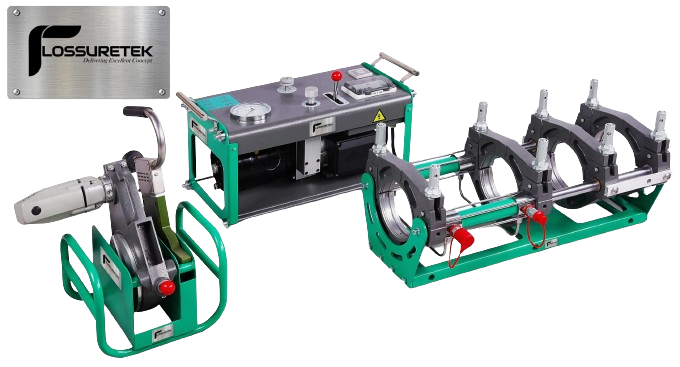

Hydraulic Butt Fusion Machine FHD200 63MM-200MM | FLOSSURETEK

Detailed Information

Hydraulic Butt Fusion Machine FHD200 63MM-200MM

The FHD200 Butt Fusion Welding Machine from FLOSSURETEK is designed to meet the demanding requirements of various applications, ensuring precise and reliable fusion welding. Key application areas include:

- Water Infrastructure: Ideal for joining thermoplastic pipes in water supply networks, guaranteeing secure and leak-free connections.

- Gas Distribution Systems: A reliable solution for welding pipes in gas distribution systems, ensuring the integrity of gas infrastructure.

- Industrial Pipelines: Suited for a range of industrial applications utilizing thermoplastic pipes, providing durable fusion joints.

- Mining Industry: The FHD200 excels in the mining sector, delivering efficient fusion welding for pipelines critical to mining operations, ensuring dependable and durable connections for water, chemicals, or other resources.

Product Details | |||

WELDING RANGE O.D. | 63 – 200 MM | WELDING RANGE INCH | 2″ – 6″ IPS |

POWER SUPPLY | 220V±10%, 50/60HZ | TEMPERATURE RANGE | MAX. 280ºC |

HEATER POWER | 1.0 KW | PACKING DIMENSION | 820*400*380 MM |

TRIMMER POWER | 0.75 KW | 440*400*520 MM | |

PUMP POWER | 1.1 KW | 650*340*380 MM | |

WORKING PRESSURE RANGE | 0 – 80 BAR | GROSS WEIGHT | 105 KGS |

FEATURES

Machine Chassis

- The integral frame features a quick and detachable structure, facilitating rapid maintenance and repair.

- The compact and robust frame structure resists deformation and oil leakage when handling thick pipes with extreme parameters.

- Key hydraulic components are sourced from industry-leading suppliers, primarily from Germany, Italy, and Japan.

Heating Plate & Trimmer

- Utilizes Teflon material from a leading industry brand, reducing adhesion between the heating plate and melted plastic for an extended service life.

- Ergonomic operation handle designed in accordance with ergonomic principles.

- Employs a powerful electric drill for efficient pipe milling with a long service life.

- The stainless steel construction of the junction box ensures corrosion resistance.

- Each side of the heating plate maintains a temperature difference of less than 3°C.

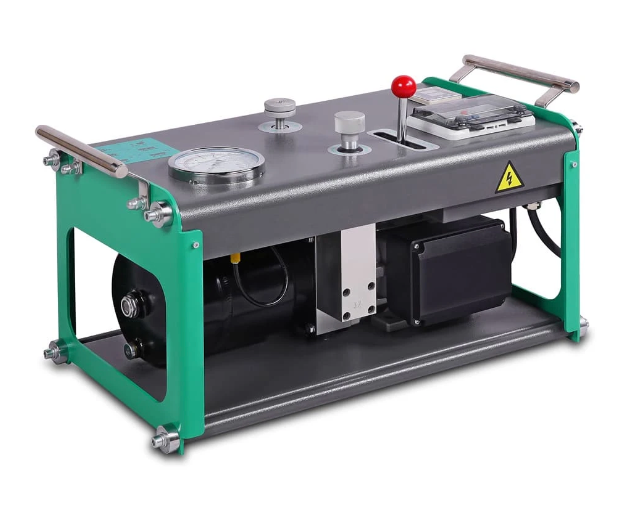

Power Station

- Robust hydraulic power with a maximum system pressure of up to 80 bar.

- Compact and robust frame structure resists deformation under external pressure.

- The integral frame features a quick and detachable structure for efficient maintenance and repair.

- Precise temperature control reduces the discrepancy between actual and displayed temperature values, ensuring welding quality.

- Pressure valves employ cartridge valves for quick maintenance and repair.