| Categories | Hydraulic Butt Fusion Machines |

|---|---|

| Brand | FLOSSURETEK |

| Model | FHD160 BEE |

| Certificate | CE, ISO9001 |

| Packing Material | Plywood Box |

| MOQ | 1set |

| Working Range in mm | (63*) 90mm – 250mm |

| Working Range in Inch | 2″ – 6″ IPS |

| Working Pressure Range | 0 – 80Bar |

| HDPE Welding Standard Applied | ISO21307, DVS2207/1, ASTM F2620 etc. |

Hydraulic Butt Fusion Machine FHD250 90MM-250MM (3" IPS - 10" IPS)

Detailed Information

Hydraulic Butt Fusion Machine FHD250 (63*)90MM-250MM (3″ IPS -10″ IPS)

The FHD250 Butt Fusion Welding Machine from FLOSSURETEK is designed to meet the demanding requirements of various applications, ensuring precise and reliable fusion welding. Key application areas include:

- Water Infrastructure: Ideal for joining thermoplastic pipes in water supply networks, guaranteeing secure and leak-free connections.

- Gas Distribution Systems: A reliable solution for welding pipes in gas distribution systems, ensuring the integrity of gas infrastructure.

- Industrial Pipelines: Suited for a range of industrial applications utilizing thermoplastic pipes, providing durable fusion joints.

- Mining Industry: The V250 excels in the mining sector, delivering efficient fusion welding for pipelines critical to mining operations, and ensuring dependable and durable connections for water, chemicals, or other resources

Product Details | |||

WELDING RANGE O.D. | (63*) 90 – 250 MM | WELDING RANGE INCH | 3″ – 10″ IPS |

POWER SUPPLY | 220V±10%, 50/60 HZ | TEMPERATURE RANGE | MAX. 280 ºC |

HEATER POWER | 2.0 KW | PACKING DIMENSION | 830*520*500 MM |

TRIMMER POWER | 1.5 KW | 560*540*600 MM | |

PUMP POWER | 1.1 KW | 650*340*380 MM | |

WORKING PRESSURE RANGE | 0 – 80 BAR | GROSS WEIGHT | 192KGS |

FEATURES

Machine Chassis

- The integral frame features a quick and detachable structure, facilitating rapid maintenance and repair.

- The compact and robust frame structure resists deformation and oil leakage when handling thick pipes with extreme parameters.

- Key hydraulic components are sourced from industry-leading suppliers, primarily from Germany, Italy, and Japa

Heating Plate & Trimmer

- Utilizes Teflon material from a leading industry brand, reducing adhesion between the heating plate and melted plastic for an extended service life.

- Each side of the heating plate maintains a temperature difference of less than 3°C.

- The stainless steel construction of the junction box ensures corrosion resistance.

- Employs a powerful electric drill for efficient pipe milling with a long service life.

- Ergonomic operation handle designed in accordance with ergonomic principles.

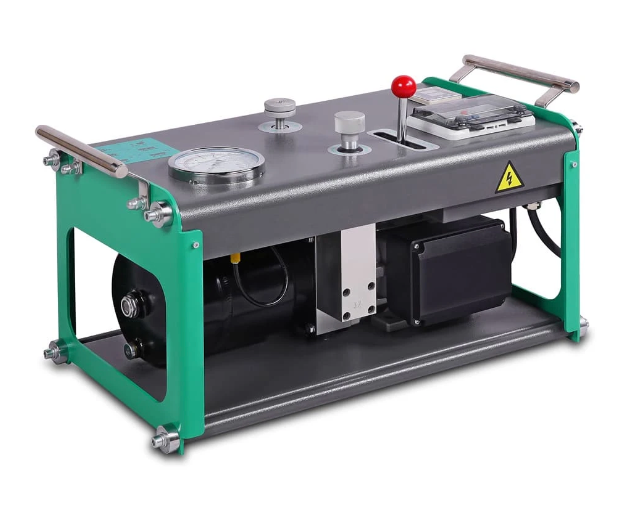

Power Station

- Robust hydraulic power with a maximum system pressure of up to 80 bar.

- Pressure valves employ cartridge valves for quick maintenance and repair.

- Precise temperature control reduces the discrepancy between actual and displayed temperature values, ensuring welding quality.

- The integral frame features a quick and detachable structure for efficient maintenance and repair.

- Compact and robust frame structure resists deformation under external pressure.